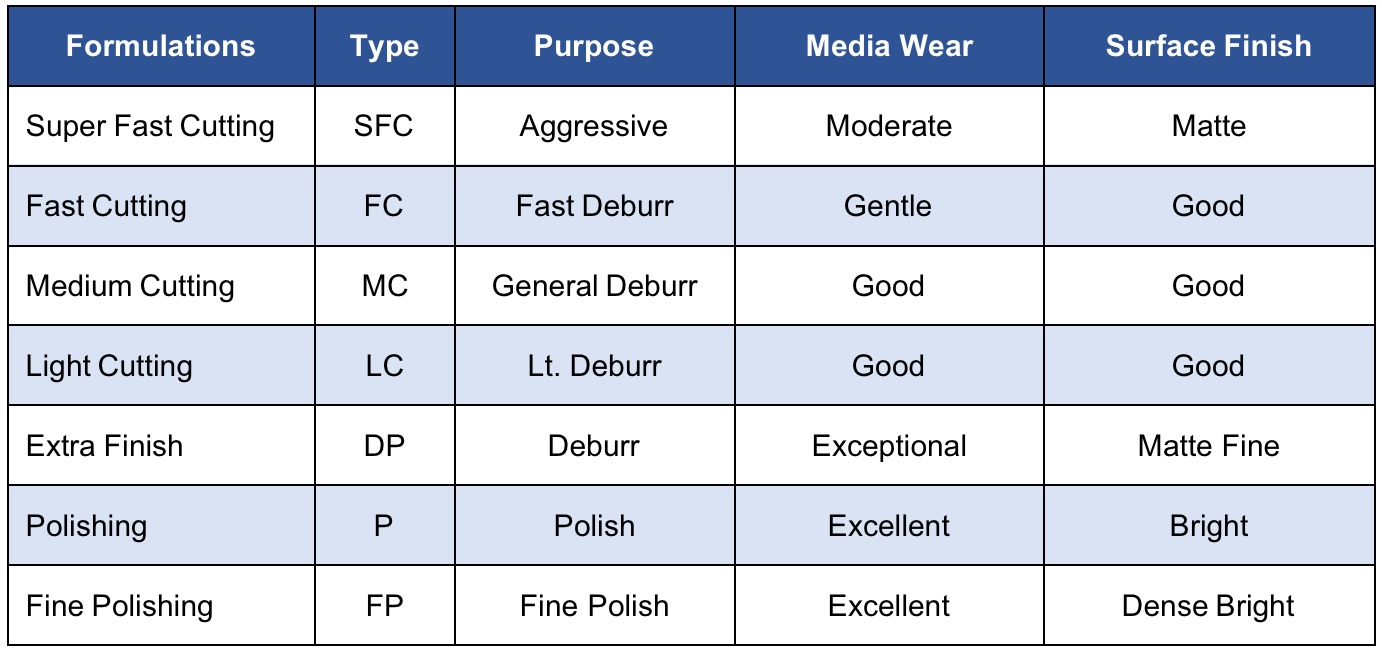

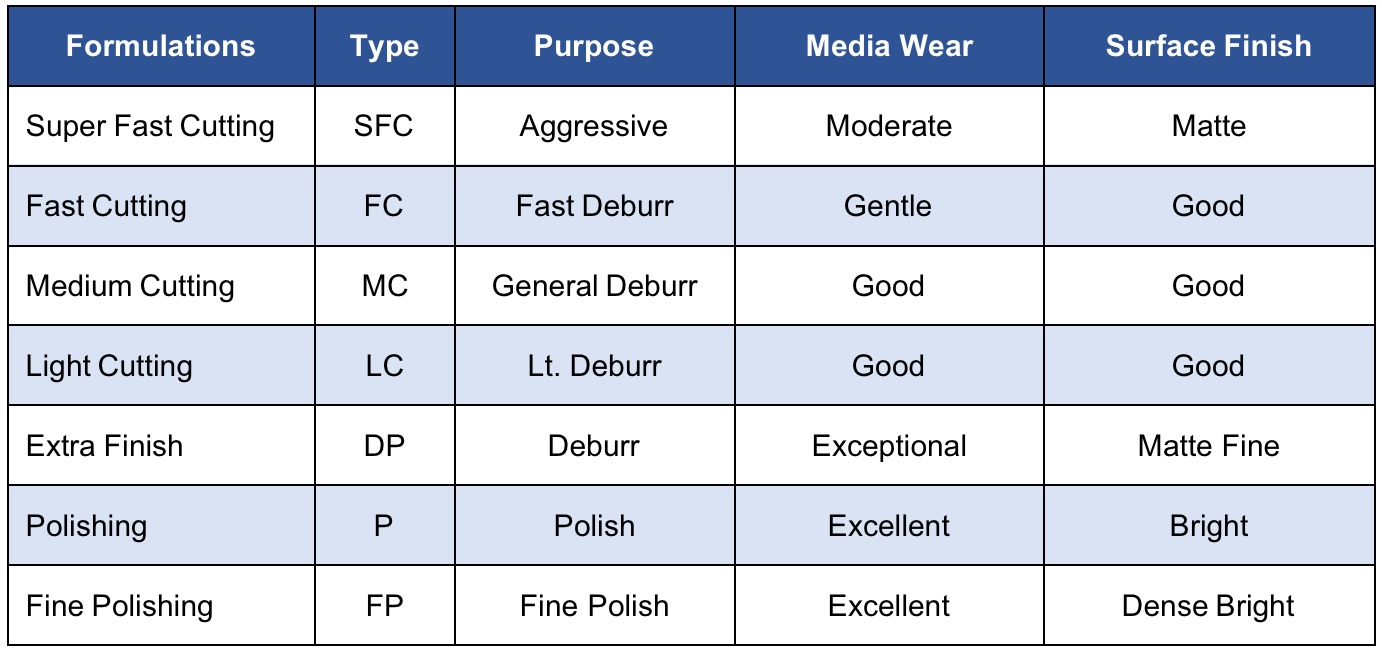

Ceramic media comes in a variety of forms to suit a range of mass finishing processes. Here are seven types of ceramic media and their respective applications:

Super Fast Cutting - This type of ceramic media is ideal for heavy-duty deburring, edge breaking, and surface improvement. It can handle even the toughest of materials and is suitable for high-volume production runs.

Fast Cutting - Similar to Super Fast Cutting, but with a slightly lower abrasiveness. This type of ceramic media is recommended for general deburring, edge breaking, and surface improvement.

Medium Cutting - This ceramic media offers a balance between speed and finesse. It is suitable for general surface improvement, light deburring, and removing small defects.

Light Cutting - For delicate finishing tasks, Light Cutting ceramic media is a perfect choice. It is suitable for surface refinement, improving surface roughness, and removing fine defects.

Extra Cutting - This type of ceramic media is designed for extremely fine surface refinement and polishing. It's ideal for achieving a mirror-like finish.

Polishing - This ceramic media is used for high-quality polishing, finishing, and lapping. It provides a smooth, uniform finish and can be used on a variety of materials.

Fine Polishing - Ideal for the final stage of polishing, Fine Polishing ceramic media delivers a bright, shiny finish. It's ideal for delicate and intricate parts and is suitable for use on a variety of materials.

Each type of ceramic media has its unique properties, making them suitable for different applications. Choosing the right type of ceramic media is key to achieving the desired result in mass finishing processes.