Vibratory finishing has emerged as the go-to mass finishing process in recent years. While some may mistakenly use the term "vibratory finishing" interchangeably with "mass finishing," it's important to note that other processes exist, including the use of centrifugal barrel machines, centrifugal disc finishing machines, and rotary barrel machines. For particularly unique applications, specialized surface finishing machines may also be employed.

In vibratory finishing, parts are processed in a vibratory bowl or tub for a variety of surface treatments, such as deburring, polishing, smoothing, cleaning, descaling, rust removal, and radius. The first vibratory finishing machine, which was a tub-type design, was introduced back in 1957. Five years later, in 1962, the bowl-type vibratory finishing machine was invented and brought to market.

1.1 DeburringOf all the applications in the vibratory finishing process, deburring is by far the most widespread. To accomplish this, a mild compound with a neutral pH of around 7.0 is typically used in conjunction with a high-quality ceramic media that can perform a wide variety of deburring tasks. For mild steel stamping parts, deburring can be achieved with ceramic media in a relatively short amount of time - usually between 30 to 60 minutes. On the other hand, aluminum die-casting parts require a gentler touch and can be deburred using plastic media over a period of 1 to 2 hours. When it comes to the deburring process in vibratory finishing, the compound used serves a dual purpose: not only does it remove burrs and imperfections from the surface of the part, but it also helps to clean off any residual machining oil or lubricant that may be present. |

|

This can be important in cases where the parts will be assembled or handled, as a neat and clean surface is necessary to ensure proper fit and function. By taking advantage of the deburring process in vibratory finishing, manufacturers can achieve a high-quality surface finish that is both functional and visually appealing.

|

1.2 BurnishingWhen it comes to achieving a high-quality, polished finish in vibratory finishing, the burnishing process is an important technique to consider. Typically, this process is done using steel balls, although zirconia balls can also be used in some cases. There are two primary types of steel media used in burnishing: ball-shaped and ball cone-shaped. While ball-shaped media offers superior polishing performance, ball cone-shaped media is ideal for hammering down burrs and leaving a dull edge. Regardless of the type of media used, it's critical to ensure that it is clean and free of dullness, as this can significantly impact the final finish. When selecting a burnishing compound, it's important to consider the material being finished. There are various compounds available for different materials such as stainless steel, aluminum, zinc, and copper. |

The ball burnishing process is usually carried out in a curved wall vibratory finishing machine or tub vibratory machine. In the curved wall design machine, the tumbling media rotates in a cross-sectional area, ensuring maximum surface contact between parts and media for optimal tumbling performance. Typically, the ball burnishing process takes around 20-30 minutes to achieve a brilliant, polished surface.

To ensure the best results in burnishing, it's crucial to select the right media, compound, and equipment for the job. With the right approach and attention to detail, vibratory finishing can deliver a perfect finish for a wide range of materials and applications.

1.3 SmoothingOne of the key benefits of vibratory finishing is the ability to modify the surface properties of parts using different types of media. Depending on the application and material being finished, different types of media may be selected to achieve the desired finish. For example, ceramic media is a popular choice for deburring and pre-painting finishing, as it offers an economical way to achieve a smooth surface without the need for costly additional processes. This type of media is especially effective at removing cutting marks left behind by machining or wheel grinding processes, which are common in many component manufacturing operations. In contrast, plastic media is often preferred for soft metal materials such as aluminum, copper, and zamak3, as it can deliver a superior pre-plating finish without damaging the metal surface. By using the right media for the job, manufacturers can achieve a high-quality finish that meets their precise specifications and requirements. |

|

In some applications, a matt finish surface with increased surface roughness is desired. This property can be achieved with ceramic media and is particularly important in the automotive industry for applications such as friction pads. By using the right type of media and finishing process, manufacturers can achieve a surface that is not only functional but also visually appealing.

Overall, vibratory finishing offers a wide range of options for modifying the surface properties of parts, making it a versatile and cost-effective solution for a variety of manufacturing applications. By selecting the right media and process for the job, manufacturers can achieve the precise finish they need to meet the demands of their customers and stay competitive in their industry.

|

1.4 Cleaning and degreasingWhen cleaning oily and greasy parts, a vibratory finishing machine is a good choice. Running the machine in a pass-through mode is the most effective way to get the job done quickly and efficiently, resulting in a higher output. The size of the machine's diameter also plays an important role in the cleaning process. The larger the machine, the longer the parts will stay in it, and the better the cleaning results will be. To achieve the best results in the cleaning process, porcelain media and steel tumbling media are the recommended options. These media types have minimal wear and don't leave any debris on the parts' surfaces. They also don't decrease in size over time, which can be costly and can risk lodging in the parts. However, the cleaning compound is the primary contributor to the cleaning process. The type of compound, the dosing rate, and the concentration are all critical factors related to performance. For cleaning parts that are greasy and oily, a strong acidic compound is required to clear off the fatty and oily substance from the metal surface. |

While a hot solution can reduce the degreasing and cleaning time, it's best to use cold water instead. This is because a hot solution can soften the PU lining and result in premature wear. By following these guidelines, you can ensure that your parts come out of the cleaning process looking their best.

1.5 Rust RemovalProcessing parts with high-temperature methods such as laser cutting, plasma cutting, and welding can lead to the formation of an undesirable oxidation layer on the metal surface. Unfortunately, this layer can prevent paint or plate from adhering well to the metal, resulting in poor-quality finishes. The solution? Vibratory finishing, which effectively removes the oxide layer and leaves the metal surface smooth and ready for the next procedure. But here's the thing: the oxide layer can be thick and stubbornly attached to the metal, making it tough to remove. That's why ceramic media with strong cutting power is the go-to choice for this process. Depending on the severity of the oxidation layer, a strong cutting compound may be necessary to reduce processing time. In some special applications, hydrochloric acid, sulfuric acid, or a mixture of the two can be used to remove the oxide layer. So if you want to ensure that your parts come out looking their best, a vibratory finishing process is a must. Not only will it remove the oxidation layer, but it will also leave your metal surface smooth and ready for a flawless finish. |

|

|

1.6 RadiusingRadiusing, also known as edge rounding or edge breaking, is an essential process for creating smooth and rounded edges on metal components. This process is particularly important for metal parts that come into direct contact with users, as it helps to prevent injuries and makes handling the parts much easier for workers. During the vibratory finishing process, edge rounding is typically carried out in conjunction with deburring and surface material removal. This helps to create a perfectly finished surface that is both visually appealing and safe to use. Whether you're working with small metal components or larger industrial parts, edge rounding is a critical step in creating a high-quality, reliable product. |

2.1 PartsWhen it comes to vibratory finishing, the size of the parts plays a critical role in determining the type of machine to use. If you're dealing with small parts, such as pins and tabs that are produced in high volume, a vibratory bowl finishing machine is ideal. This type of machine ensures that the parts are tumbled and polished evenly while reducing the risk of part-to-part impingement. However, for larger parts like transmission gear parts, a vibratory bowl channel is more suitable as it is faster and easier to retrieve the parts by hand. On the other hand, when dealing with even larger parts like a ceramic-coated exhaust pipe, the situation is a little different. In such cases, most vibratory bowl channels are unable to accommodate the parts, and a vibratory tub is the preferred choice. This type of machine can handle larger and more cumbersome parts while still providing the necessary tumbling and polishing action to produce a high-quality finish. |

|

|

|

2.2.1Straight Wall Processing Bowl --- Series SW:The straight wall vibratory finishing machine is a versatile solution that is ideal for medium-sized parts deburring and cleaning. It is a standard machine without an internal separation deck, making it an economical choice for those with no specific requirements for their parts. With its straightforward design, this type of vibratory finishing machine is easy to operate and maintain, making it a popular choice for many manufacturers. Whether you're looking to deburr, clean, or polish your parts, the straight wall vibratory finishing machine can get the job done efficiently and effectively. |

2.2.2 Curved Wall Processing Bowl --- Series CWThe vibratory finishing process with curved wall design is widely used due to its excellent flow of parts and media. The unique design of this machine results in a shorter process cycle, saving time and cost in high-polishing applications. One of the primary applications of the curved wall vibratory machine is in the ball burnishing process. When burnishing with stainless steel tumbling media, the vibrator motor is upgraded to support increased loading weight. Standard vibratory machines tend to cause small or lightweight parts to float at the outer surface. However, with the increased tumbling performance of curved wall machines, these parts have excellent movement with the media mass, resulting in a smoother finishing process. |

|

|

2.2.3 Straight Wall Processing Bowl with Separation --- Series SWSIf you're handling large volumes of parts, manually separating each individual piece after vibratory finishing is a tedious and time-consuming task. Fortunately, you can save yourself the trouble with a vibratory finishing machine that comes equipped with an internal separation deck. The separation process is easy and efficient. Once the parts are finished, you simply pull down the lever on the right side of the machine and the mass of the parts flows onto the separation screen. The smaller media easily passes through the screen, while the larger parts remain above the screen. Once you've removed the finished parts, you can close the lever and continue with the next batch of processing. The integration of an internal separation deck saves time and effort while allowing for efficient, high-volume finishing. |

2.2.4 Curved Wall Processing Bowl with Separation --- Series CWSThe curved wall design vibratory finishing machines are an innovation on the straight wall design, providing a faster and more efficient tumbling process. The cascade of media and parts in the curved wall design helps to reduce processing time while increasing the overall polishing quality. However, due to the narrower chamber width, larger parts may not be able to complete a full turnover inside the machine. Moreover, the media and parts mass capacity is lower than in the straight wall design. |

|

|

2.2.5 On-Table Vibratory TumblerAn on-table vibratory tumbler consists of a small tub or bowl that vibrates rapidly to create a tumbling motion of the media and parts inside. The vibration intensity and speed can be adjusted to achieve the desired finish quality and processing time. The tub or bowl has a perforated bottom, which allows the media and parts to move freely while separating from the liquid compound or water. On-table vibratory tumblers are ideal for small and medium-sized parts, delicate or intricate components, or low-volume production runs. They can be used in various industries, such as jewelry making, watchmaking, dental and medical device manufacturing, electronics, and hobbyists. |

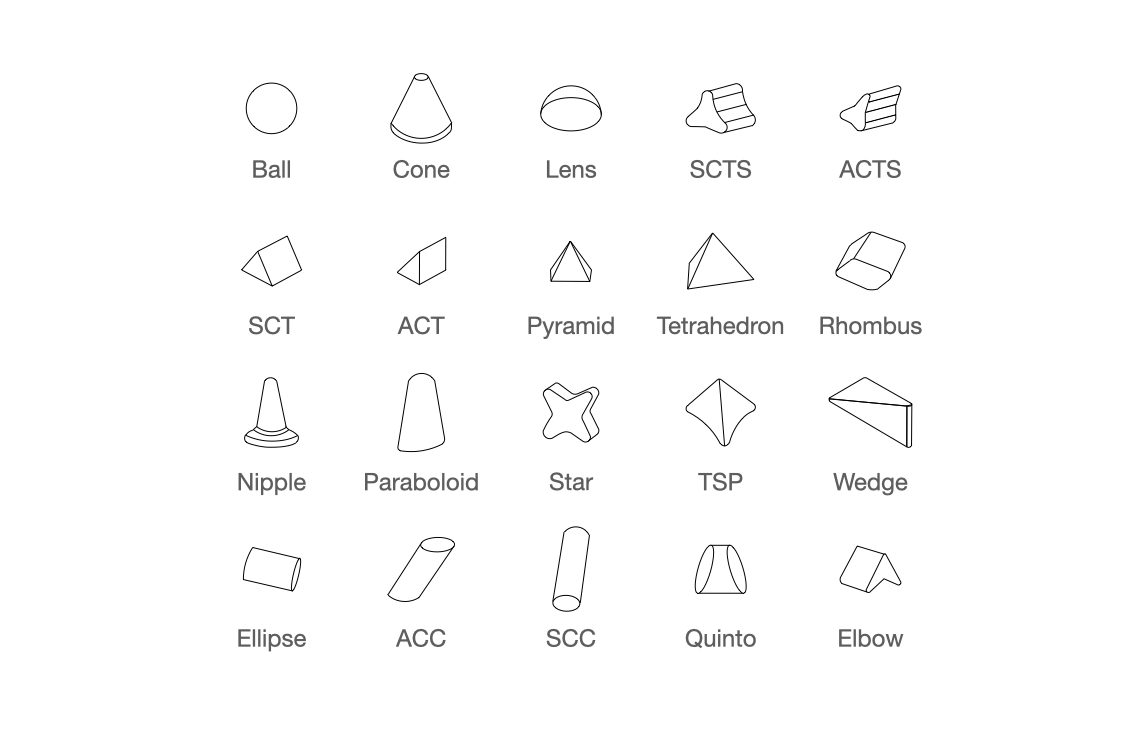

2.3.1 Consider the material of your parts:Different types of media are suitable for different materials. For example, ceramic media with brown aluminum oxide abrasive is commonly used for the general deburring of hard metal materials, while plastic media is often used for aluminum and zinc die-casting parts. 2.3.2 Determine the desired finish:Different types and shapes of media can produce different finishes. For example, ball-shaped media can produce a smoother finish, while pyramid-shaped media can be more aggressive in cutting and producing a matte finish. |

|

The size of the media should be smaller than the parts to ensure efficient tumbling and prevent parts from getting lodged. If the parts are much smaller than the media, you may need to consider using a reverse separation process.

The shape of the media should be chosen based on the shape and complexity of the parts being tumbled. Choose media with shapes that are less likely to lodge in or damage your parts.

The amount of media in the tumbler is critical to achieving a successful tumbling process. Generally, a 3:1 media-to-parts ratio is recommended for most tumbling applications. However, delicate parts may require a higher media-to-parts ratio to prevent parts-on-parts impingement.

It's important to test and adjust the tumbling process to ensure the desired finish is achieved. Make adjustments to the type, size, shape, and amount of media until the desired finish is achieved.

Choosing the right compound for your vibratory finishing process is a critical step in achieving the desired finishing result. Consider the material being finished, the desired finishing result, and any environmental and safety factors when choosing a compound, and be sure to follow the manufacturer's instructions when diluting the compound.

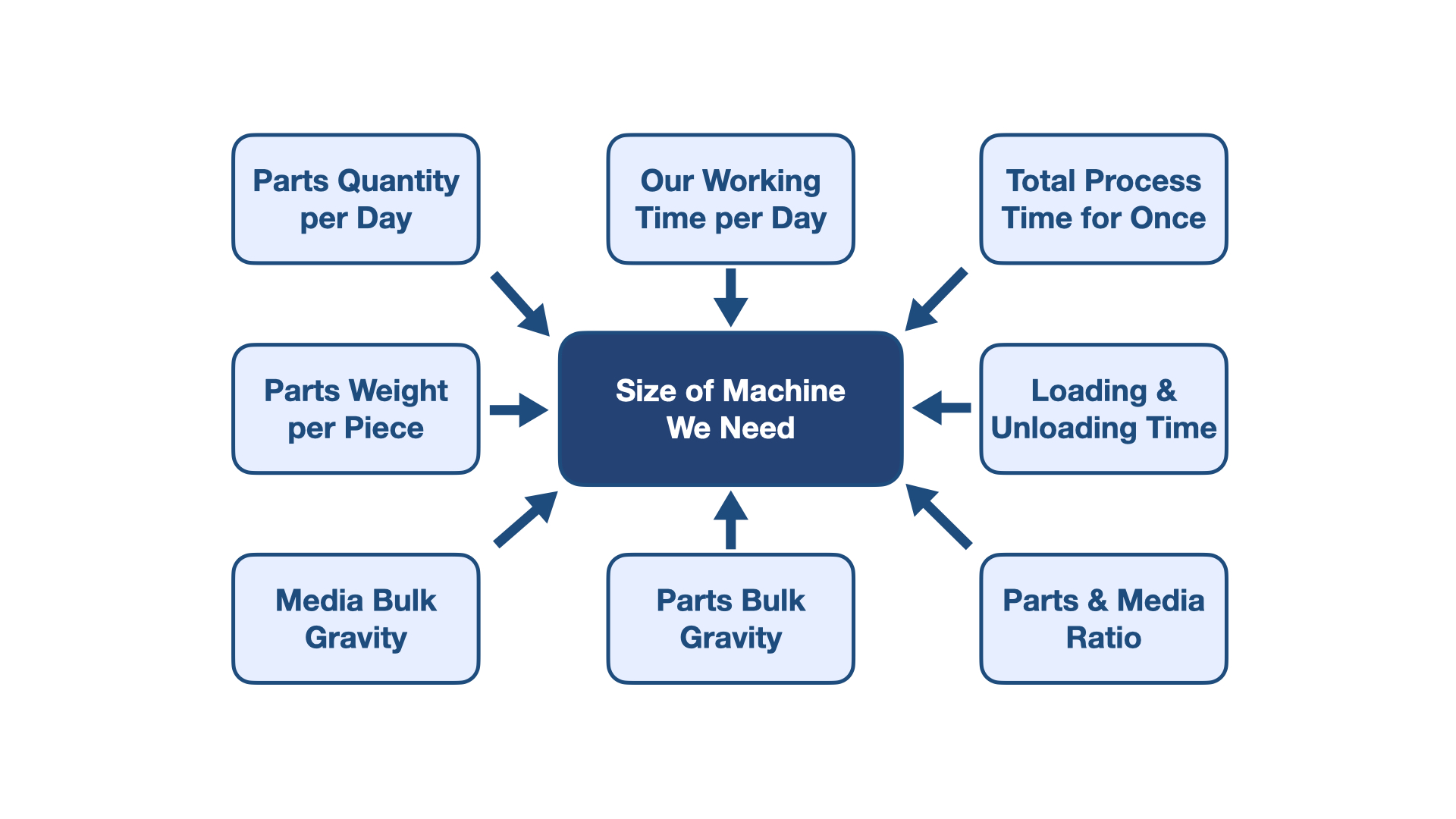

Make the estimation of how many parts you need to run every day, how much time to finish them, and the parts-to-media ratio.

If you can manage without an internal separation system, then it's better to buy a machine without one. Before using the machine, it's important to properly install it. If you have experience with installation, you can do it yourself using our installation guide. However, if you're a first-time user, it's better to seek the help of an electrician in your area.

Choosing 3-phase electricity, such as 380V, 460V, or 480V, is preferable over a single-phase voltage of 220V. 3 phase electricity is safer and usually grounded, and it can help reduce amperage flow.