A vibratory finishing machine is an equipment used for deburring, polishing, cleaning, and other surface finishing processes. It is an efficient and cost-effective solution to improve the surface quality of metal and plastic parts. After knowing the right machine type, how to choose the right supplier is still a big trouble. In this article, we will discuss how to choose the right supplier and the importance of choosing the right supplier based on your vibratory finishing machine needs.

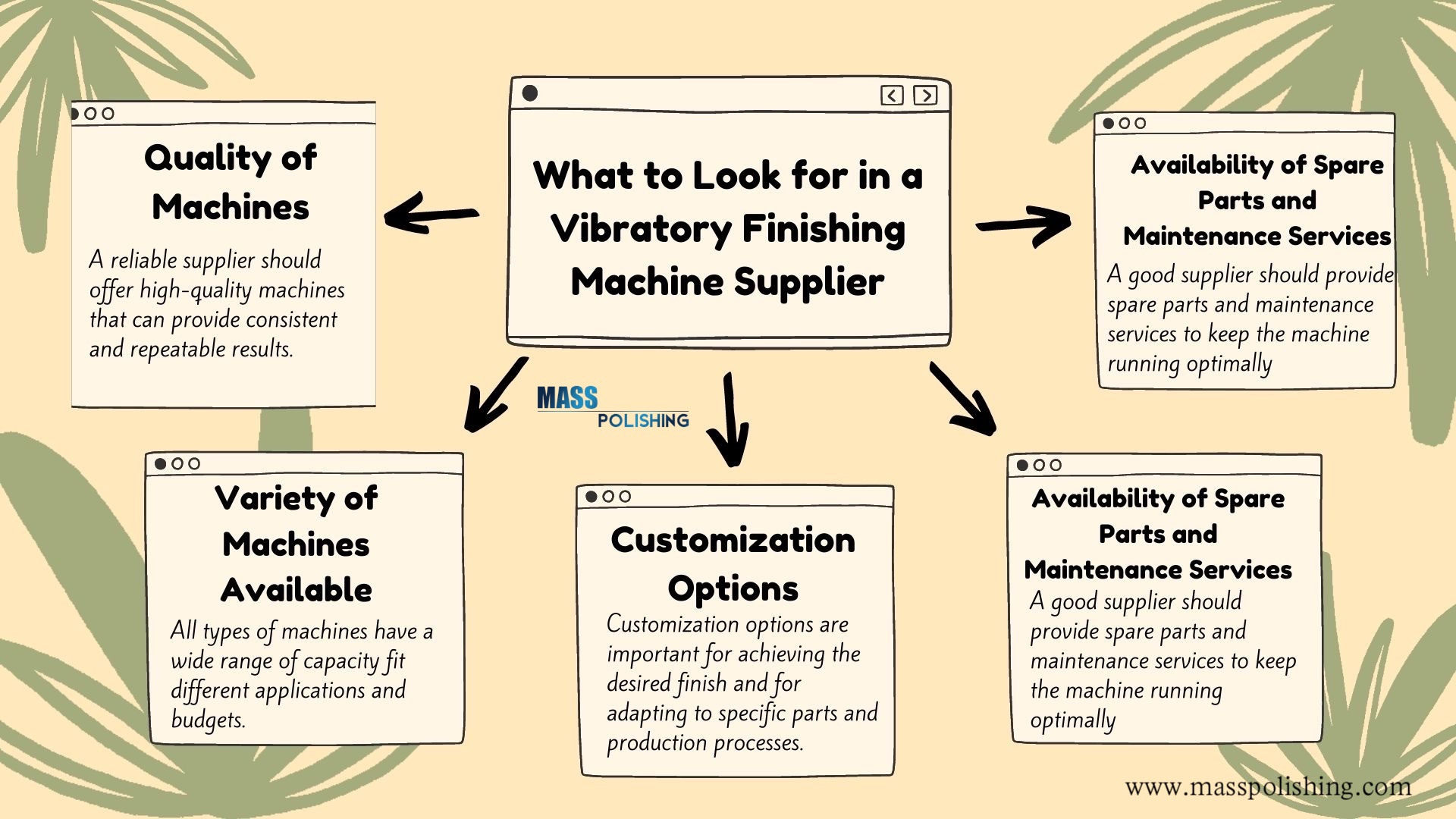

2. What to Look for in a Vibratory Finishing Machine Supplier

A reliable supplier should offer high-quality machines that can provide consistent and repeatable results.

Laser Cutting → Welding → Shot Blasting → PU Casting → Painting → Testing

We use high-quality raw materials and control every production step strictly. After production, we will test all parts, especially the running of the motor and PU quality. We promise that the machine has excellent performance. The warranty period of our machine is two years, in case of non-human damage.

There are five types of vibratory finishing machines in Mass Polishing, including Vibratory Finishing Machines with Straight Wall Processing Bowls, Vibratory Finishing Machines with Curved Wall Processing Bowls, Vibratory Finishing Machines with Straight Wall Processing Bowls with Separation, Vibratory Finishing Machines with Curved Wall Processing Bowl with Separation, and On-Table Vibratory Tumblers.

All types of machines have a wide range of capacity fit different applications and budgets.

|

|

|

|

|

Customization options are important for achieving the desired finish and for adapting to specific parts and production processes. Mass Polishing here can provide nearly all kinds of media and many optional settings, such as a soundproof cover, water dosing pump, control panels, automatic separations, automatic liquid systems, etc.

|

Soundproof Cover |

Control Box |

Pneumatic Separate Flap |

|

Consumables |

A good supplier should provide spare parts and maintenance services to keep the machine running optimally. Mass Polishing has a team of experienced technicians who can provide routine maintenance services online. We also have a well-stocked inventory of parts and components prepared for rarely broken times.

Look for a supplier with a good reputation and positive customer reviews to ensure reliability and quality. With over 25 years of surface treatment experience in the area, we have long-term cooperation with world-famous brands of Chinese processing plants and received many recognitions and honors. (Click here to see our story)

Mass Polishing has lots of materials and shapes of media. We have ceramic media which is usually used in the deburring process, plastic media which is good at soft metal finishing, and stainless steel finishing media which can do mirror-like polishing. Also, we have other special media, such as G3P, corn cob drying media, walnut shell media, wooden media, etc. The media can be customized to fit the specific finishing needs of the parts.

Machines can be customized with additional accessories to enhance the finishing process. Such as a soundproof cover, water dosing pump, control panels, automatic separations, automatic liquid systems, etc. The most popular accessory is the pneumatic separating flap that can depart the parts and media automatically.

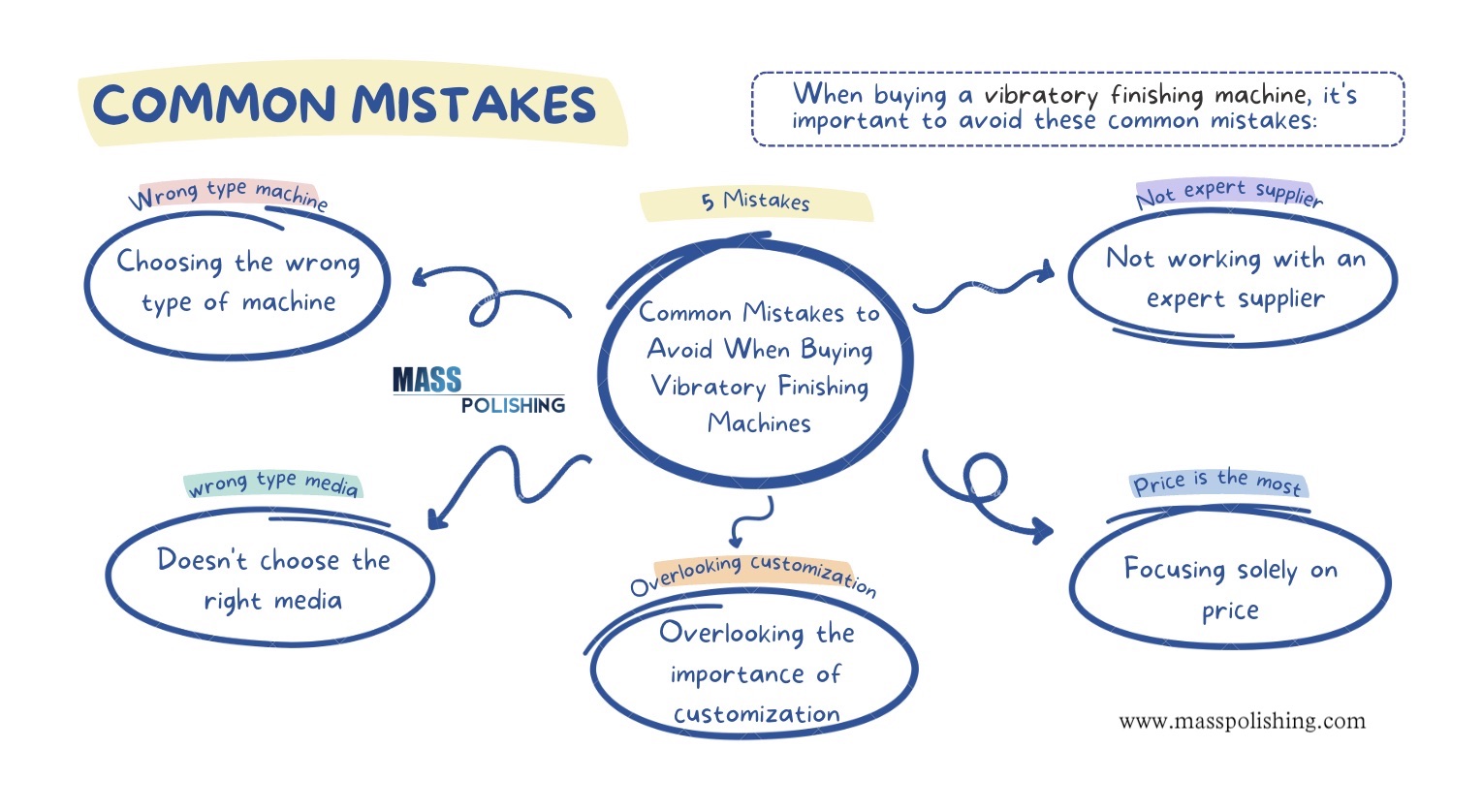

When buying a vibratory finishing machine, it's important to avoid these common mistakes:

Make sure you choose the right type of machine based on the parts being finished and the desired finish. For example, finishing machines with separation are better at mass finishing.

The right media can make your finishing process smooth and successful. The wrong media may destroy your parts. Media size is not the smaller the better polishing performance. Media material is not the harder the stronger deburring. Contact with Mass Polishing, the sooner the better.

Customization options can make a big difference in the performance of your machine. Customization mass finishing systems can solve all the surface finishing problems at one processing line. (Click here for further information)

While price is important, it shouldn't be the only factor in your decision. To tell the truth, soundproof covers can really protect your hearing and make the operators more enjoy their work.

Working with an expert supplier can help you make the right decision and get the most out of your machine. Mass Polishing will always be here to support your surface finishing.

We have our own factory that produces all kinds of surface treatment products, including vibratory finishing machines, centrifugal barrel machines, centrifugal disc machines, mass finishing media, etc. Our company was certified for ISO9001:2015 Quality Management System and machines are certified in CE.

We are committed to providing competitive pricing and excellent customer service, ensuring that our clients have access to the best surface treatment solutions on the market. Whether you are in the automotive, aerospace, medical, jewelry, electronics, sporting goods, or food processing industry, Mass Polishing has the expertise and solutions you need to achieve the desired surface finish on your products.

With over 25 years of experience, a knowledgeable staff, and a wide range of high-quality products and solutions, we are able to provide customized solutions to meet the unique needs of our clients.

Choosing the right vibratory finishing machine and the supplier is crucial for the success of your business. So, choose Mass Polishing today and take your finishing operations to the next level!