Centrifugal barrel finishing machines are used to polish, deburr, and finish a variety of small parts and components. They work by tumbling the parts and media inside a barrel that is rotated at high speeds, causing the media to grind against the parts and produce a polished or finished surface. These machines can be used on a wide range of materials, including metals, plastics, and ceramics. They are commonly used in industries such as automotive, aerospace, and medical device manufacturing. Do you have any specific questions about centrifugal barrel finishing machines?

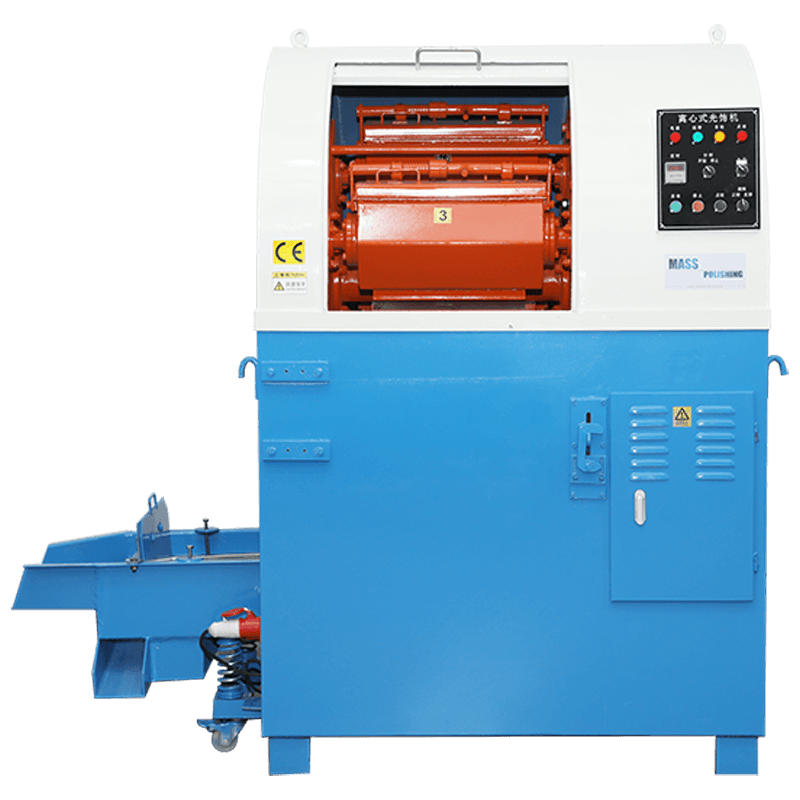

Centrifugal barrel finishing machines are mechanical finishing systems that are used to smooth, deburr, and polish a variety of different workpieces. They typically consist of a series of barrels that rotate around a central axis, with the workpieces and abrasive media placed inside the barrels. The barrels are typically made of a durable material such as steel or ceramic, and are designed to withstand the high speeds and forces that are generated during the finishing process. Other characteristics of centrifugal barrel finishing machines may include:

Variable speed control: Many centrifugal barrel finishing machines allow the user to adjust the speed of the barrels, which can affect the intensity of the finishing process.

Multiple barrels: Some machines have multiple barrels that can be used simultaneously, allowing the user to process more workpieces at once.

Automatic loading and unloading: Some centrifugal barrel finishing machines are equipped with automated systems for loading and unloading the workpieces, which can improve efficiency and reduce the risk of operator injury.

Multiple processing stages: Some machines have multiple processing stages, allowing the workpieces to be subjected to different finishing processes in sequence.

Adjustable vibration: Many centrifugal barrel finishing machines are equipped with adjustable vibration settings, which can affect the intensity of the finishing process.