An Efficient Automatic Mass Finishing System -- The Linear Continuous Flow Vibrator

The Linear Continuous Flow Vibrator is a versatile Automatic Mass Finishing System used in a wide range of industries to create high-quality finishes on parts and components. This type of machine uses a continuous flow of media and parts through a series of channels or compartments, providing consistent and efficient processing of parts.

Linear Continuous Flow Vibrators come in a variety of sizes and configurations to meet the specific needs of different industries and applications. They can be used to deburr, polish, clean, and descale parts made from various materials, including metal, plastic, and ceramic.

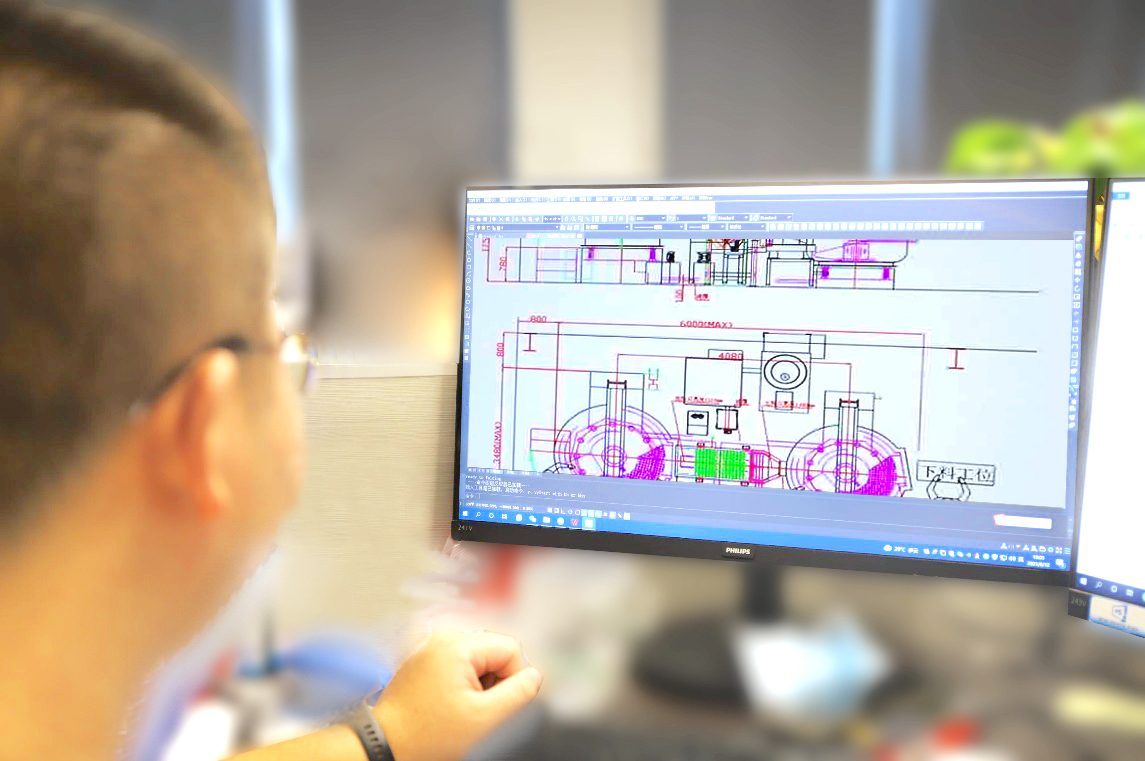

The Linear Continuous Flow Vibrator works by using a vibration motion that moves the parts and media in a linear path, creating the desired finish on the parts. The machine is designed with a conveyor belt that moves the parts through a series of compartments or channels, where they come into contact with the media. The media, which can be made of various materials such as ceramic, plastic, or steel, grinds against the parts, removing any excess material and creating the desired finish.

One of the main advantages of the Linear Continuous Flow Vibrator is its ability to process a high volume of parts in a short amount of time. This makes it an ideal choice for manufacturers who need to finish a large number of parts quickly and efficiently.

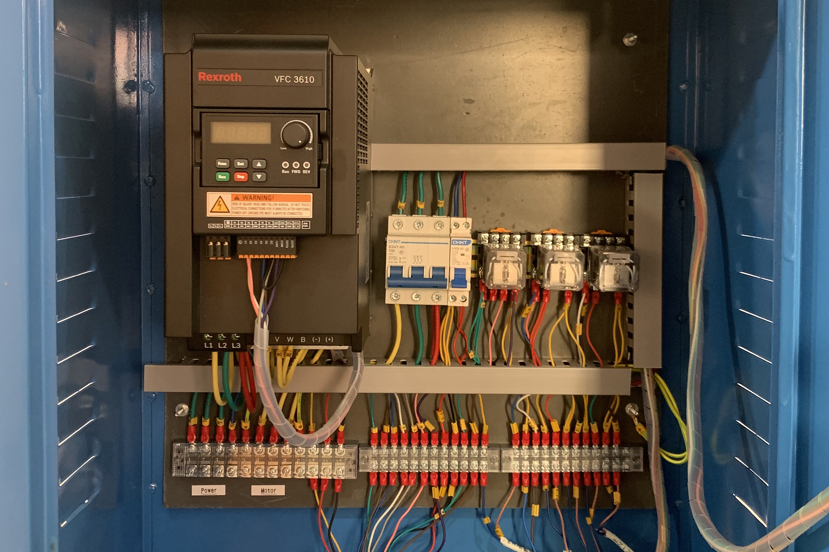

In addition to its high efficiency, the Linear Continuous Flow Vibrator is also designed with safety in mind. The machine is equipped with safety features such as guards and interlocks, which help prevent accidents and protect operators.

Overall, the Linear Continuous Flow Vibrator is a versatile and efficient Automatic Mass Finishing System that can provide businesses with high-quality finishes on a wide range of parts and components. With its ability to process a large volume of parts quickly and safely, it is an ideal choice for manufacturers looking to improve their finishing processes.