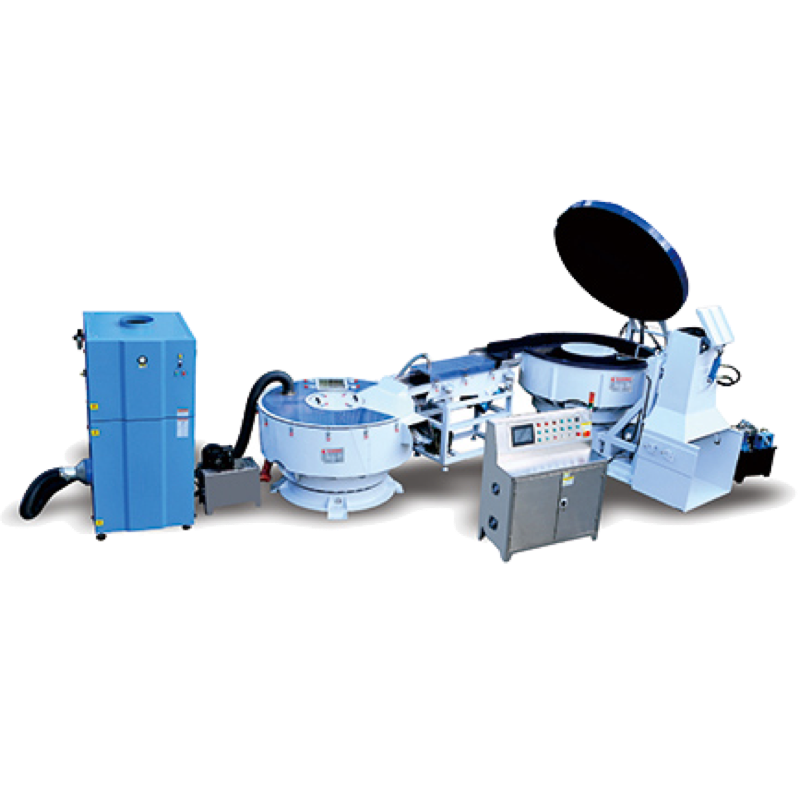

An Automated and Efficient Finishing Solution -- Mass Finishing & Washing & Heating Auto Line

Mass Finishing & Washing & Heating Auto Line is an automatic mass finishing system that streamlines finishing processes, making them more efficient and effective. The system is designed with three main components: mass finishing, washing, and heating, which work together to provide a comprehensive finishing solution.

The mass finishing component of the system is designed to remove any excess material from the parts, creating a uniform finish. The parts are loaded into the system and are then subjected to various media, which grind against the parts, removing any burrs, sharp edges, or other imperfections.

After the mass finishing process, the parts are moved to the washing component, where they are cleaned thoroughly to remove any remaining media, oils, or other contaminants. The system is equipped with various washing mechanisms, including high-pressure nozzles and ultrasonic waves, which ensure that the parts are cleaned thoroughly.

Finally, the parts move to the heating component of the system, where they are dried and heated to the desired temperature. The heating component can be customized to meet the specific needs of different applications, ensuring that the finished parts are of the highest quality.

Overall, Mass Finishing & Washing & Heating Auto Line is an ideal solution for manufacturers looking to streamline their finishing processes. The system is automated, efficient, and effective, providing high-quality finishes on a wide range of parts and components.