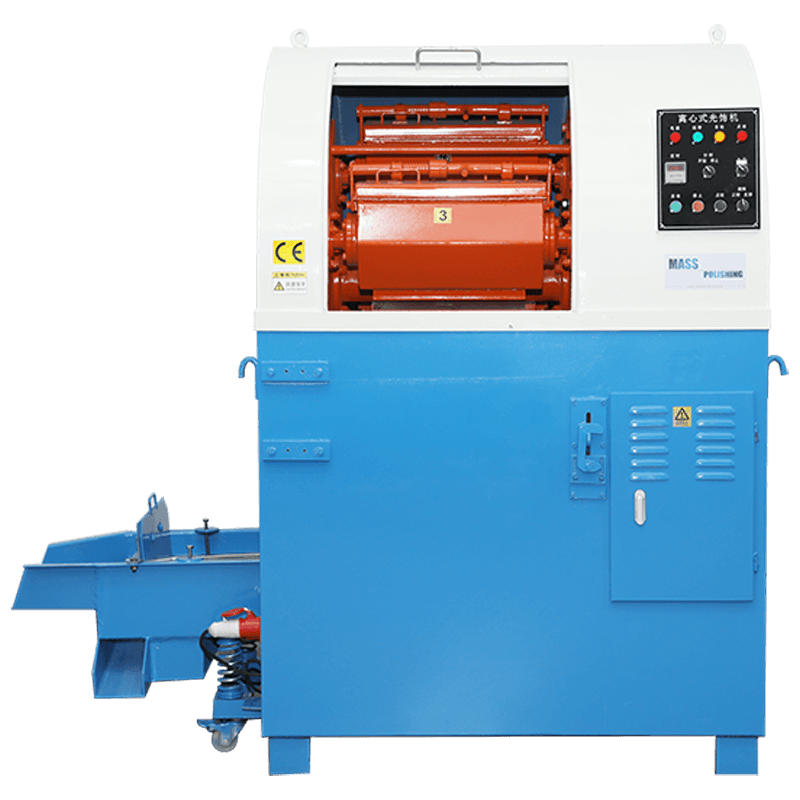

Here are some tips for maintaining a centrifugal barrel finishing machine:

7.1 Follow Mass Polishing's maintenance guidelines:

Make sure to follow our recommendations for maintaining the machine, including how often to perform maintenance tasks and what types of lubricants and cleaning agents to use.

7.2 Keep the machine clean:

Regularly clean the machine to remove any abrasive media, debris, or coolant that may have accumulated on the surface.

7.3 Lubricate moving parts:

Make sure to lubricate any moving parts on the machine to reduce friction and wear.

7.4 Check and replace worn parts:

Regularly inspect the machine for any worn or damaged parts and replace them as needed.

7.5 Store the machine properly:

When not in use, make sure to store the machine in a clean, dry location to prevent corrosion or damage.

7.6 Keep a maintenance log:

Keep a record of all maintenance tasks that are performed on the machine, including the date, the task that was performed, and any problems that were identified or resolved. This will help you to track the machine's performance over time and identify any potential issues before they become major problems.

By following these maintenance guidelines, you can help to ensure that your centrifugal barrel finishing machine is operating at its best and has a long, productive lifespan.