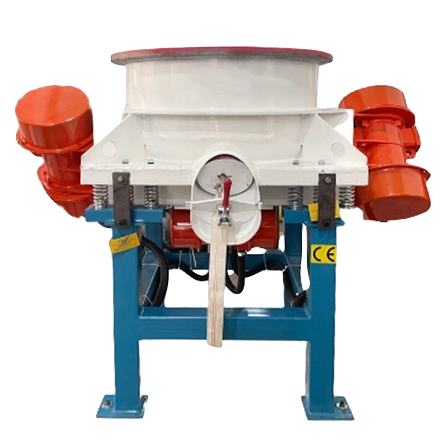

A ceramic wheel polishing machine is a type of machine used to polish wheels by using tumbling media. This machine typically consists of a chamber that is vibratory, along with a fixture that makes the wheel stable, or consists of a chamber and a drag to rotate the wheel. The ceramic tumbling media used in the machine is an abrasive material that helps to remove surface imperfections to the wheel. It is usually used in the first deburring process. The media comes in various shapes and sizes, depending on the type of wheel being polished and the level of surface finish desired. The ceramic wheel polishing machine works by placing the wheel to be polished inside the chamber along with the tumbling media. The machine then rotates or vibrates, causing the media to rub against the wheel's surface, removing any imperfections and providing a high shine. The process can take anywhere from a few minutes to several hours, depending on the desired level of polishing. Ceramic wheel polishing machines are commonly used in industrial applications for polishing wheels, but they are also used in smaller-scale applications for polishing automotive wheels, motorcycle wheels, and other similar types of wheels. Some models of ceramic wheel polishing machines come with automatic timers and speed controls, allowing users to customize the process to their specific needs.